Effect of in-situ stress on the cracking and permeability enhancement in coal seams by deep-hole cumulative blasting

-

摘要: 针对地应力对煤层深孔聚能爆破致裂增透问题,在分析钻孔围岩应力场、爆生裂隙扩展及动态卸载效应的基础上,对不同地应力条件下聚能爆破作用过程及裂隙发育特征进行了数值模拟,并通过在不同埋深下的聚能爆破现场试验,探讨了地应力对煤层深孔聚能爆破致裂增透的作用。结果表明:在高地应力煤层进行深孔聚能爆破时,地应力在煤层深孔聚能爆破裂隙扩展不同阶段的作用存在较大区别,在未进行聚能爆破时,钻孔围岩应力状态及形变特征由钻孔形态以及地应力共同决定。在聚能爆破作用初始阶段,由于聚能爆破对围岩产生的冲击作用明显强于地应力,因此爆生裂隙在初期的扩展方向主要由聚能装药结构控制,沿聚能槽开口方向形成定向裂隙;随着裂隙向四周扩展,爆破作用逐渐减弱,地应力作用逐渐显现,钻孔围岩在地应力作用下产生切向压应力,限制了爆破径向裂隙扩展。同时,与主应力方向不同的煤体裂隙在较强的剪应力作用下逐渐沿最大主应力方向偏转。当爆破作用产生的等效动态应力无法继续使煤体进一步压缩时,钻孔围岩内积聚的弹性应变能开始朝爆破中心方向释放,形成新的裂隙。此外,不同方向上的裂隙扩展范围受侧压系数控制,当垂直主应力一定时,随着侧压系数增大,最小主应力方向的裂隙范围进一步减小。Abstract: With the gradual development of coal mining to deeper levels, the in-situ stress of coal seams shows an increasing trend, resulting in a gradual decrease in permeability, and the stress state of the coal and rock mass and the properties of the surrounding rock also change. The mechanical properties and mechanical parameters of coal and rock mass greatly differ between depths, which influences the cracking and permeability enhancement effect of coal seam deep-hole cumulative blasting. Aiming at the problem of the increasing permeability of coal seams by deep-hole cumulative blasting under in-situ stress, on the basis of an analysis of the stress field of the surrounding rock and the stress of the blasting crack surface, the process of cumulative blasting and crack development characteristics under different confining pressures were numerically simulated. Through field tests of cumulative blasting under different buried depths, the influence of in-situ stress on the cracking and permeability enhancement effect of coal seam deep-hole cumulative blasting was discussed. The results show that the role of in-situ stress differs greatly between the stages of radial crack expansion of coal seam deep-hole cumulative blasting. Before blasting, the stress state and deformation characteristics of the borehole surrounding rock are determined by borehole shape and in-situ stress. In the initial stage of cumulative blasting, the impact of cumulative blasting on the surrounding rock is obviously stronger than in-situ stress. Therefore, the expansion direction of blasting cracks in the initial stage is mainly determined by the cumulative structure, and directional cracks are formed along the opening direction of the cumulative charge groove. With the crack extension, the blasting effect is gradually weakened, and the in-situ stress is dominant. The surrounding rock of the borehole produces tangential compressive stress under the in-situ stress, which limits the radial crack expansion of blasting. Meanwhile, the coal cracks that are not collinear with the principal stress gradually deflect toward the direction of the maximum principal stress under the action of strong shear stress. When the equivalent dynamic stress produced by blasting cannot continue to compress the coal, the elastic strain energy accumulated in the surrounding rock of the borehole begins to release toward the blasting center, causing the coal to crack and produce new cracks. In addition, the crack expansion range in different directions is controlled by the lateral pressure coefficient. When the vertical principal stress is constant, the crack range toward minimum principal stress further decreases with increasing lateral pressure coefficient.

-

随着煤矿开采逐渐向深部发展,煤层地应力呈增加趋势,导致透气性逐渐降低,瓦斯抽采难度加大。如何增大煤层透气性系数、提高瓦斯抽采率,保障煤矿安全高效生产是当前亟待解决的关键问题[1]。深孔聚能爆破技术利用特殊装药结构的聚能效应提高炸药爆炸后在聚能方向的能量分布,煤层增透专家学者进行了大量研究并取得了重要进展[2-5]。但随着煤层埋深增加,煤岩体应力状态和围岩属性均会发生改变,不同深度煤岩体表现出来的力学特性和力学参数存在较大区别[6-8],进而对煤层深孔聚能爆破致裂增透效果产生影响。

深部煤岩体爆破致裂是爆炸载荷、爆生气体、地应力、煤岩结构及力学性质等因素共同作用的结果[9-11]。关于地应力对爆破致裂的作用,Kutter和Fairhurst[12]试验发现爆生径向裂隙会优先沿最大主应力方向扩展;穆朝民等[13-14]认为地应力对爆生裂隙扩展具有抑制作用;陈明等[15]研究表明,地应力是导致爆生裂隙区比例半径缩小的主要原因,侧压系数主导了爆生裂隙沿孔壁圆周的分布,Tao等[16]通过数值模拟也得到了类似结果;Yang和Ding[17],以及Yang等[18]通过静态加载条件下的动焦散线试验发现,爆生裂纹扩展方向在初期主要受预制裂纹方向控制,在后期受静应力影响裂纹逐渐朝加载方向偏转。此外,随着地应力逐渐升高,爆炸载荷下钻孔围岩破坏特征也会发生变化[19]。Zhang等[20]实验发现,径向裂隙扩展受围压抑制使致裂范围变小,但当围压增大到一定程度时会促进试件的反射拉伸断裂;肖思友等[10,21]认为地应力促进了围岩弹性应变能的累积,在爆炸载荷作用下使围岩弹性区演化为损伤破坏区,扩大了破岩范围。

综上所述,地应力是影响聚能爆破裂隙扩展的重要因素,而聚能爆破在不同方向上对煤体作用具有明显差异。为研究地应力在聚能爆破过程中对裂隙发育的作用,本文在分析钻孔围岩应力场、聚能爆破致裂过程、裂隙扩展特征及煤岩动态卸载效应的基础上,建立数值分析模型,研究了地应力作用下聚能爆破煤岩体裂隙扩展规律。基于试验区瓦斯地质条件及地应力分布特征,开展了煤层深孔聚能爆破试验,探讨了地应力对煤层深孔聚能爆破致裂增透的作用。为优化煤层深孔聚能爆破参数、提高深部煤层聚能爆破增透效果提供理论基础和科学依据。

1. 地应力对聚能爆破煤体致裂作用的分析

1.1 地应力作用下聚能爆破煤体致裂模型

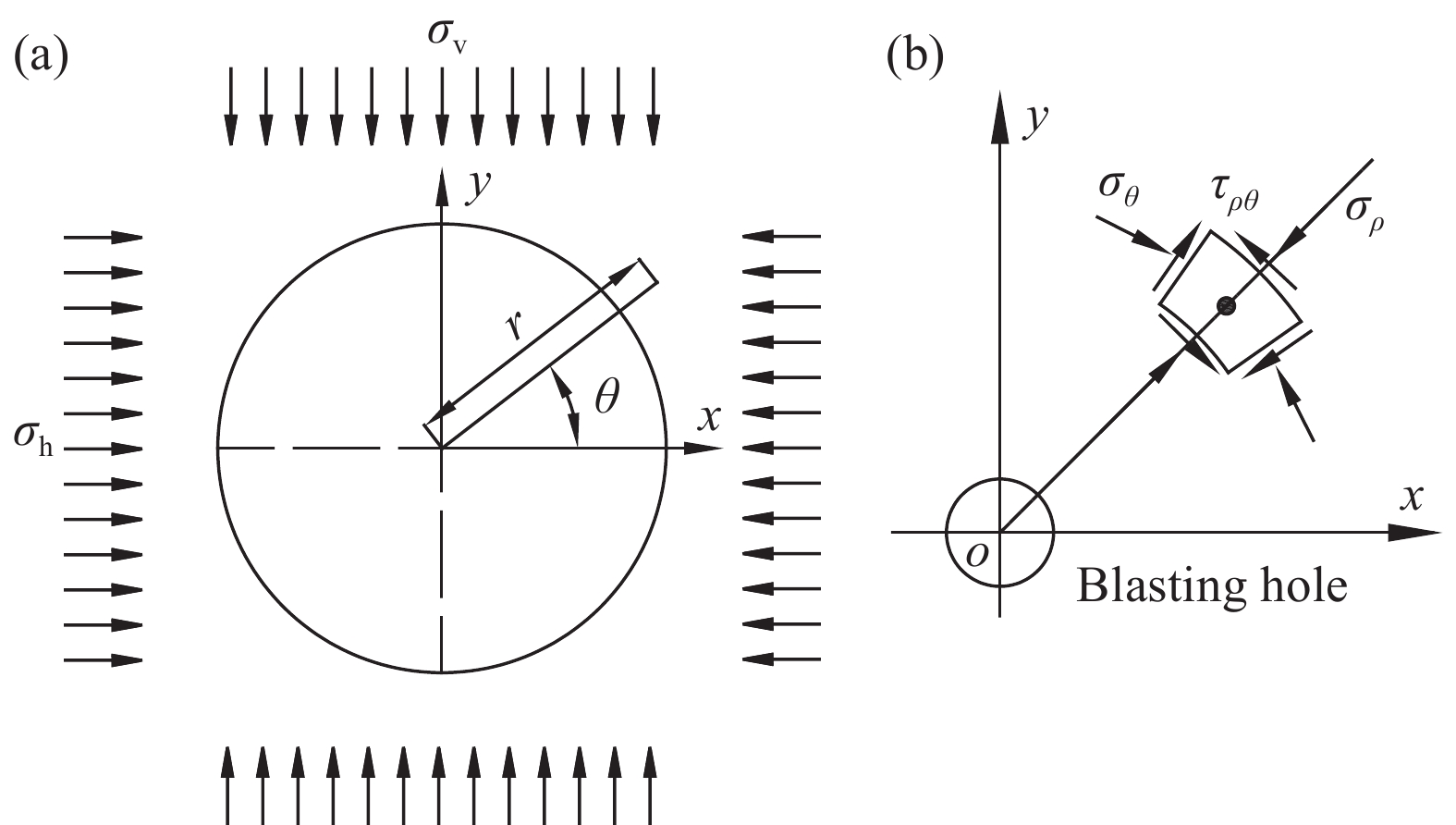

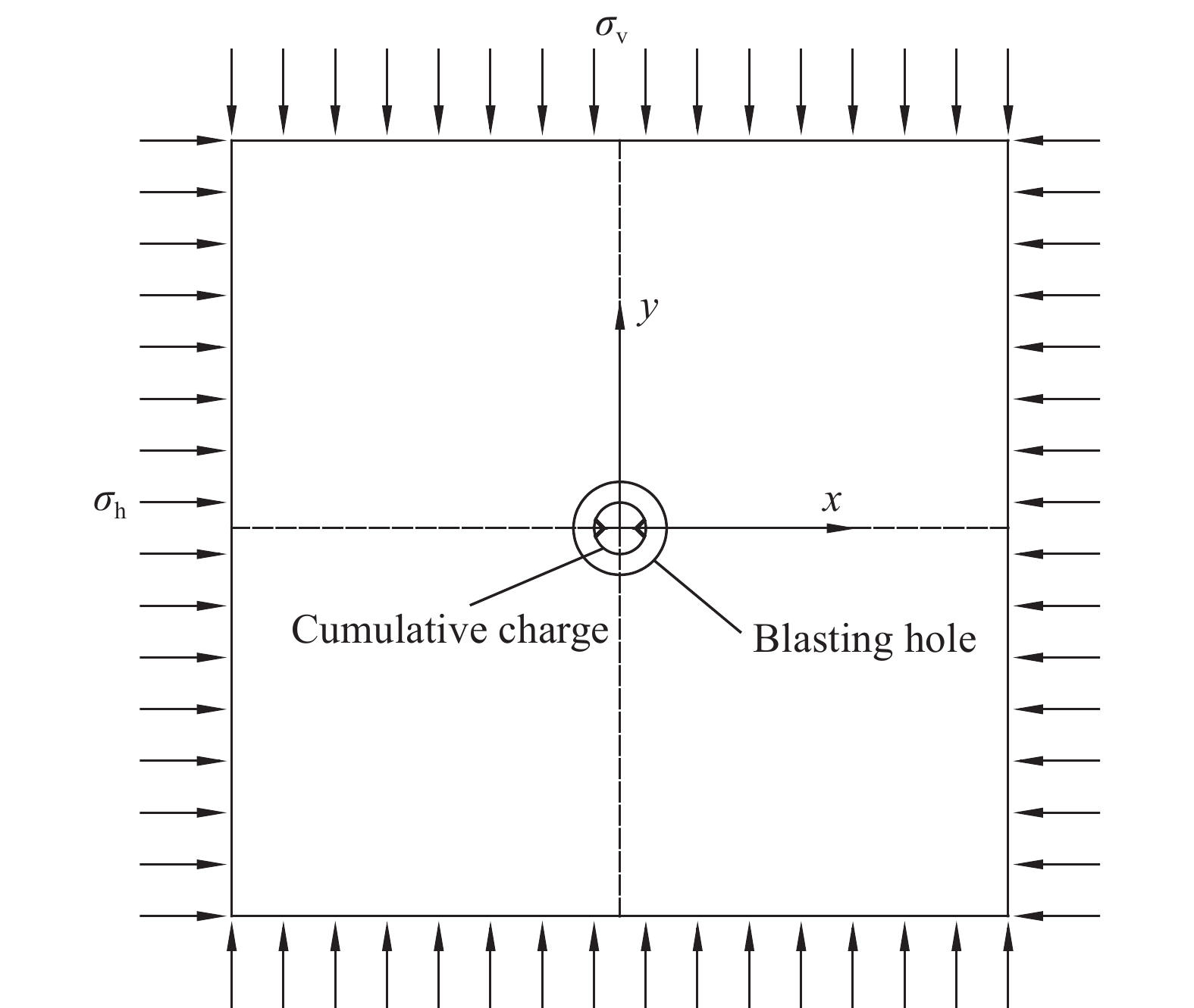

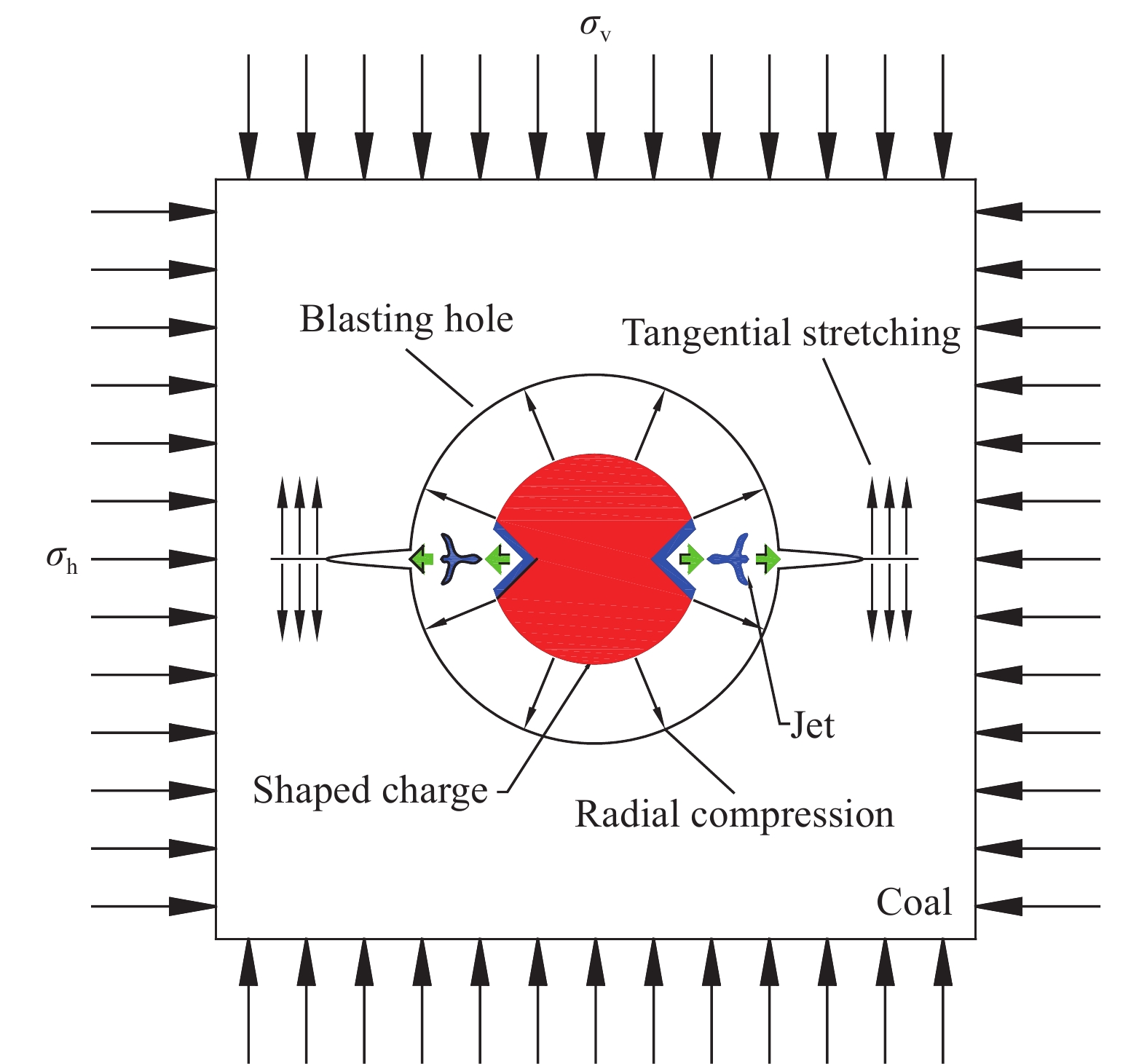

在煤层进行聚能爆破时,钻孔将受到远场垂直应力σv、水平应力σh及聚能爆破的耦合作用(图1)。

由于聚能装药长度远大于装药半径,因此该问题可以简化为平面应变问题。在聚能药包起爆前,钻孔在地应力作用下发生分区破坏。当聚能药包起爆时,不同方向上的爆破致裂过程有较大差异:在非聚能方向上,爆轰波作用钻孔围岩形成爆破粉碎区,随着爆轰波进一步向四周传播会逐渐衰减为应力波,应力波作用于塑性区以及弹性区时会产生切向拉伸应力导致径向裂隙形成;在聚能方向上,炸药起爆后先作用于聚能槽形成聚能流,在围岩破坏区形成侵彻槽,随后在爆炸冲击波及爆生气体的联合作用下,沿侵彻槽方向产生裂隙。由于聚能效应的存在,炸药产生的爆炸能量在聚能方向上更集中,相比非聚能方向的爆轰波具有更强的穿透能力,因此更易形成定向裂隙[22]。同时,钻孔围岩受地应力作用在塑性区与弹性区产生更为集中的切向压应力,影响了爆破径向裂隙的生成。

1.2 地应力作用下钻孔围岩应力分布

为探讨地应力对聚能爆破致裂作用,首先要分析爆破钻孔在地应力作用下的应力分布,此时钻孔受力如图2所示。

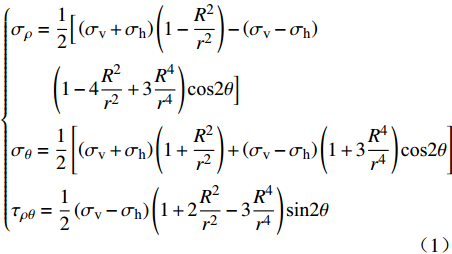

钻孔受垂直应力σv以及水平应力σh作用。基于弹性力学可得距离钻孔中心r处围岩上任一点的受力情况如下。

$$ \begin{split}\begin{cases} {\sigma _\rho } =\dfrac{1}{2}\Big[ \left( {{\sigma _{\text{v}}} + {\sigma _{\text{h}}}} \right)\left( {1 - \dfrac{{{R^2}}}{{{r^2}}}} \right) - \left( {{\sigma _{\text{v}}} - {\sigma _{\text{h}}}} \right)\\ \qquad\,\left( {1 - 4\dfrac{{{R^2}}}{{{r^2}}} + 3\dfrac{{{R^4}}}{{{r^4}}}} \right){\text{cos}}2\theta \Big] \\ {{\sigma _\theta } = \dfrac{1}{2}\left[ {\left( {{\sigma _{\text{v}}} + {\sigma _{\text{h}}}} \right)\left( {1 + \dfrac{{{R^2}}}{{{r^2}}}} \right) + \left( {{\sigma _{\text{v}}} - {\sigma _{\text{h}}}} \right)\left( {1 + 3\dfrac{{{R^4}}}{{{r^4}}}} \right){\text{cos}}2\theta } \right]} \\ {{\tau _{\rho \theta }} = \dfrac{1}{2}\left( {{\sigma _{\text{v}}} - {\sigma _{\text{h}}}} \right)\left( {1 + 2\dfrac{{{R^2}}}{{{r^2}}} - 3\dfrac{{{R^4}}}{{{r^4}}}} \right){\text{sin}}2\theta } \end{cases}\end{split} $$ (1) 其中:σρ、σθ、τρθ分别为该点处的径向、切向和剪切应力;R为钻孔半径;θ为该点与x轴的夹角。

对煤层钻孔而言,由于煤体强度相对较低,当地应力较大时孔边围岩会发生塑性形变甚至破坏,此时孔边应力会重新分布,应力集中区域向外转移,由钻孔中心向外形成塑性区和弹性区。为分析钻孔围岩的塑性区分布规律,利用库伦强度准则[23]作为塑性区边界条件进行探讨。

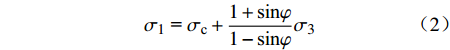

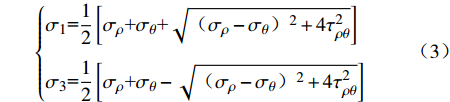

$$ {\sigma _1}{\text{ = }}{\sigma _{\text{c}}} + \dfrac{{1 + {\text{sin}}\varphi }}{{1 - {\text{sin}}\varphi }}{\sigma _3} $$ (2) 其中:σ1、σ3分别为最大、最小主应力;σc为煤体单轴抗压强度;φ为煤体的内摩擦角。

将式(1)中的各应力分量通过主应力计算公式进行表达。

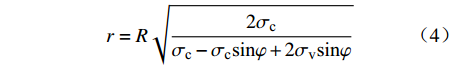

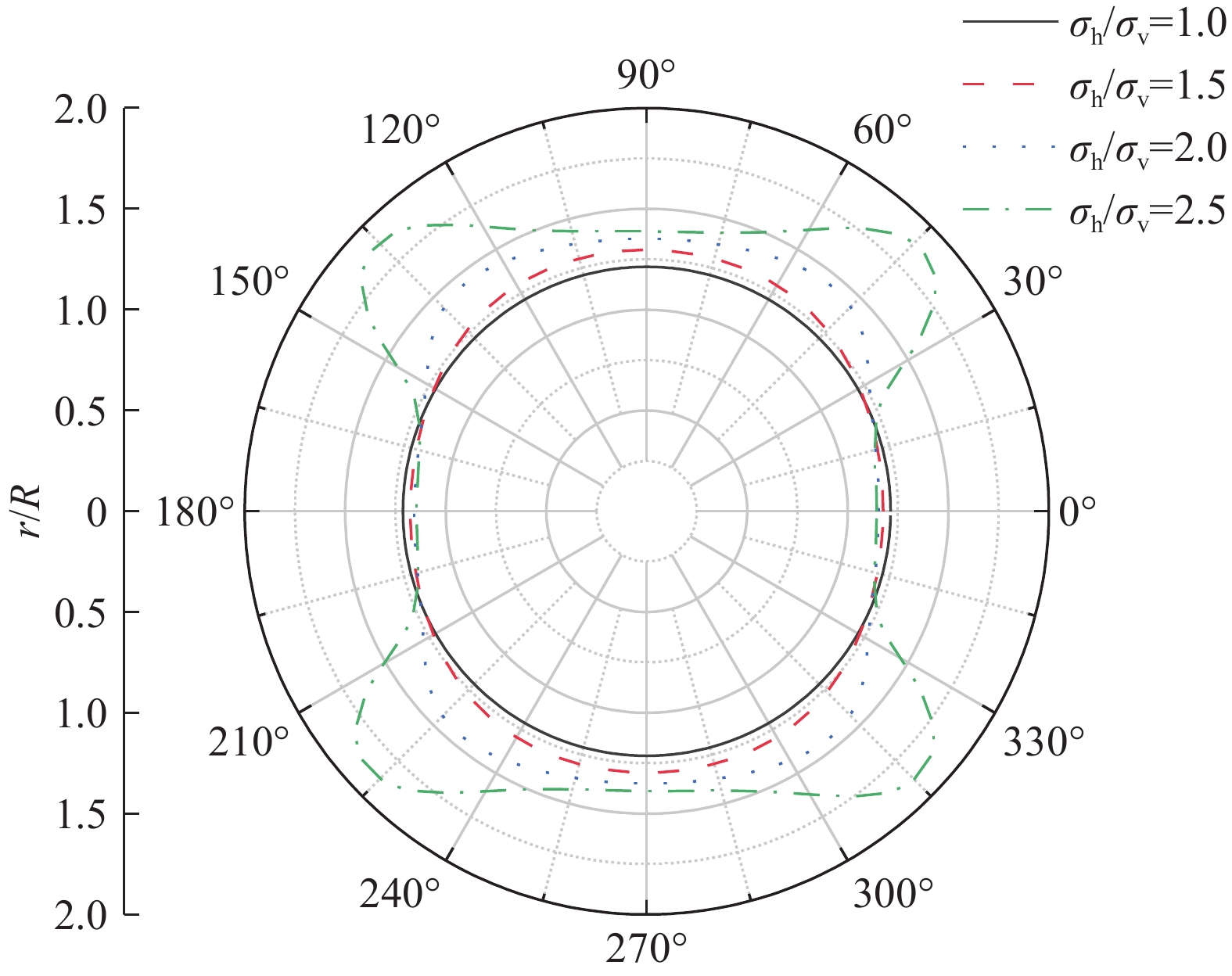

$$ \begin{cases}{\sigma }_{1}\text=\dfrac{1}{2}\left[{\sigma }_{\rho }\text+{\sigma }_{\theta }\text+\sqrt{({\sigma }_{\rho }-{\sigma }_{\theta }{)}^{2}+4{\tau }_{\rho \theta }^{2}}\right]\\ {\sigma }_{3}\text=\dfrac{1}{2}\left[{\sigma }_{\rho }\text+{\sigma }_{\theta }-\sqrt{({\sigma }_{\rho }-{\sigma }_{\theta }{)}^{2}+4{\tau }_{\rho \theta }^{2}}\right]\end{cases} $$ (3) 将式(1)、式(2)和式(3)进行联立即可求得钻孔在地应力作用下的塑性区范围。当σh/σv=1时,可得到塑性区分布函数。

$$ r = R\sqrt {\dfrac{{2{\sigma _{\text{c}}}}}{{{\sigma _{\text{c}}} - {\sigma _{\text{c}}}{\text{sin}}\varphi + 2{\sigma _{\text{v}}}{\text{sin}}\varphi }}} $$ (4) 由式(4)可知,当钻孔围压相等时,塑性区半径只与垂直应力大小以及煤体的物理力学性质有关。当σh/σv≠1时,上述联立方程组只能获得解析解,通过计算可以得到在不同侧压系数下的塑性区分布,如图3所示。

随着侧压系数的增大,塑性区半径在水平方向会有小幅减小,而在竖直方向会有一定的增加,塑性区整体逐渐由圆形向椭圆再向蝶形分布发展。受塑性区分布影响,在爆破过程中孔边蝶叶位置处的煤体在爆破前会处于破碎状态,这也会减弱爆炸能量传入煤体形成的应力波强度,进而对该方向的裂隙扩展造成影响。因此,为保证聚能药包定向致裂效果,应将聚能槽开口方向与围岩最大主应力方向保持一致。

1.3 地应力作用下聚能爆破裂隙扩展分析

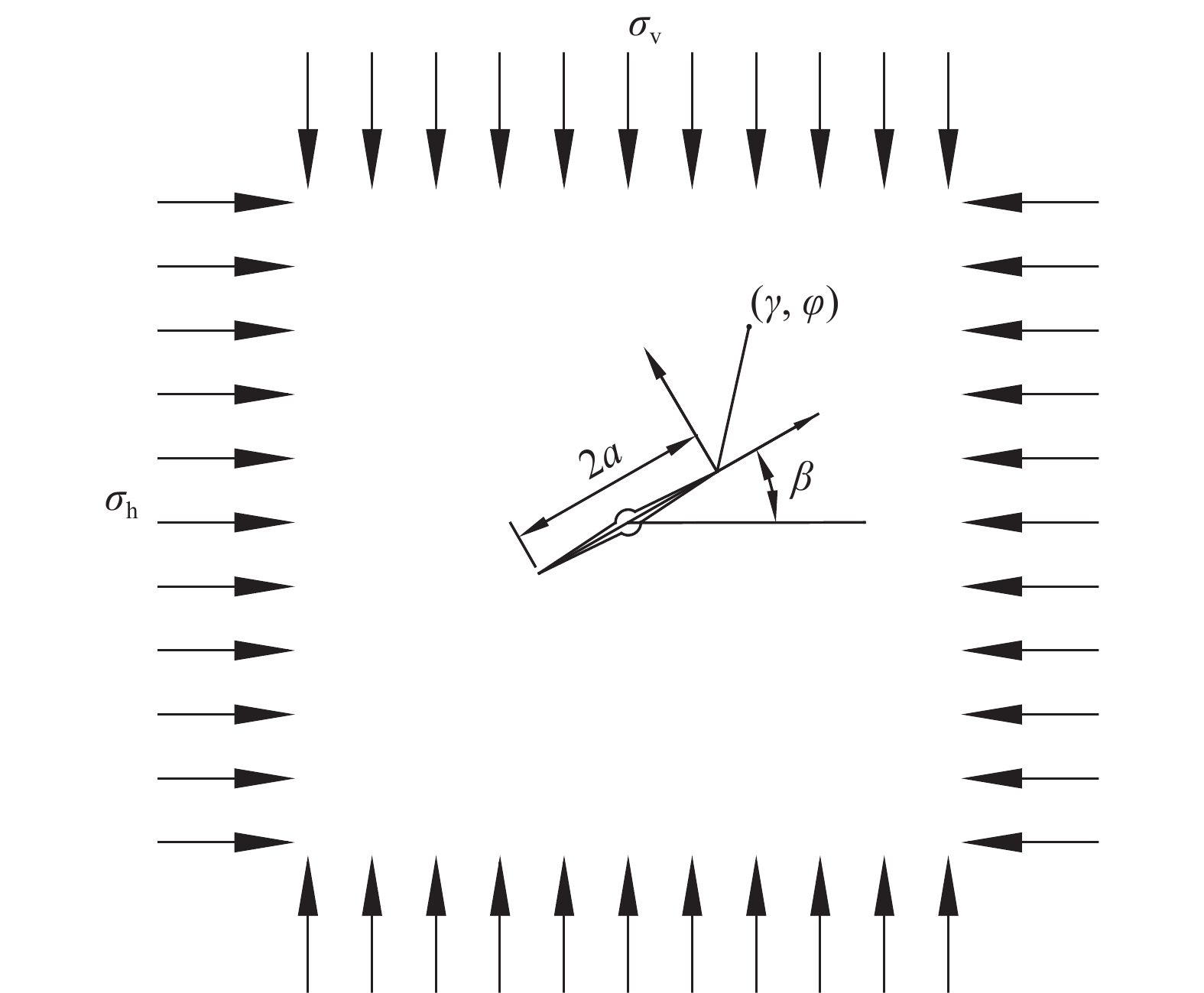

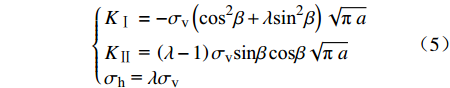

为分析地应力作用下的聚能爆破裂隙扩展规律,对爆生裂隙扩展过程进行简化,假设聚能爆破致裂过程中已形成一条长为2a、与水平方向夹角为β的裂隙,垂直应力与水平应力分别为σv和σh,如图4所示。

此时裂隙尖端应力强度因子[24]为:

$$ \left\{ \begin{gathered} {K_{{\text{Ⅰ}}}} = {{ - }}{\sigma _{\text{v}}}\left( {{\text{co}}{{\text{s}}^2}\beta + \lambda {\text{si}}{{\text{n}}^2}\beta } \right)\sqrt {{\text{π }}a} \\ {K_{{\text{Ⅱ}}}}{\text{ = }}\left( {\lambda - 1} \right){\sigma _{\text{v}}}{\text{sin}}\beta \, {\text{cos}}\beta \sqrt {{\text{π }}a} \\ {\sigma _{\text{h}}}{\text{ = }}\lambda {\sigma _{\text{v}}} \\ \end{gathered} \right. $$ (5) 其中,λ为侧压系数。

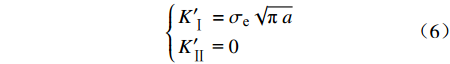

爆生裂隙在爆炸应力波以及爆生气体共同作用下形成,此时爆破作用引起的裂隙尖端应力强度因子为:

$$ \left\{ \begin{gathered} K_{\text{Ⅰ}}' = {\sigma _{\text{e}}}\sqrt {{\text{π }}a} \\ K_{{\text{Ⅱ}}}'{\text{ = }}0 \\ \end{gathered} \right. $$ (6) 其中,σe为由爆破作用引起的等效动态应力。

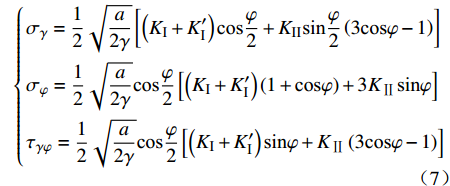

将式(5)、(6)进行叠加可得到极坐标下裂隙尖端应力场[25]为:

$$ \left\{ \begin{gathered} {\sigma _\gamma } = \dfrac{1}{2}\sqrt {\dfrac{a}{{2\gamma }}} \left[ {\left( {{K_{\text{I}}} + K_{\text{I}}'} \right){\text{cos}}\dfrac{\varphi }{2} + {K_{{\text{II}}}}{\text{sin}}\dfrac{\varphi }{2}\left( {3{\text{cos}}\varphi - 1} \right)} \right] \\ {\sigma _\varphi } = \dfrac{1}{2}\sqrt {\frac{a}{{2\gamma }}} {\text{cos}}\dfrac{\varphi }{2}\left[ {\left( {{K_{\text{I}}} + K_{\text{I}}'} \right)\left( {1 + {\text{cos}}\varphi } \right) + 3{K_{{{{\text{Ⅱ}}}}}}{\text{sin}}\varphi } \right] \\ {\tau _{\gamma \varphi }} = \dfrac{1}{2}\sqrt {\dfrac{a}{{2\gamma }}} {\text{cos}}\dfrac{\varphi }{2}\left[ {\left( {{K_{\text{I}}} + K_{\text{I}}'} \right){\text{sin}}\varphi + {K_{{{{\text{Ⅱ}}}}}}\left( {3{\text{cos}}\varphi - 1} \right)} \right] \\ \end{gathered} \right. $$ (7) 其中,σγ、σφ、σγφ分别为极坐标下裂隙尖端所受的正应力、切应力以及剪应力。

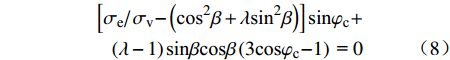

根据最大环向拉应力理论,裂隙扩展方向角φc满足∂σφ/∂φ=0,即:

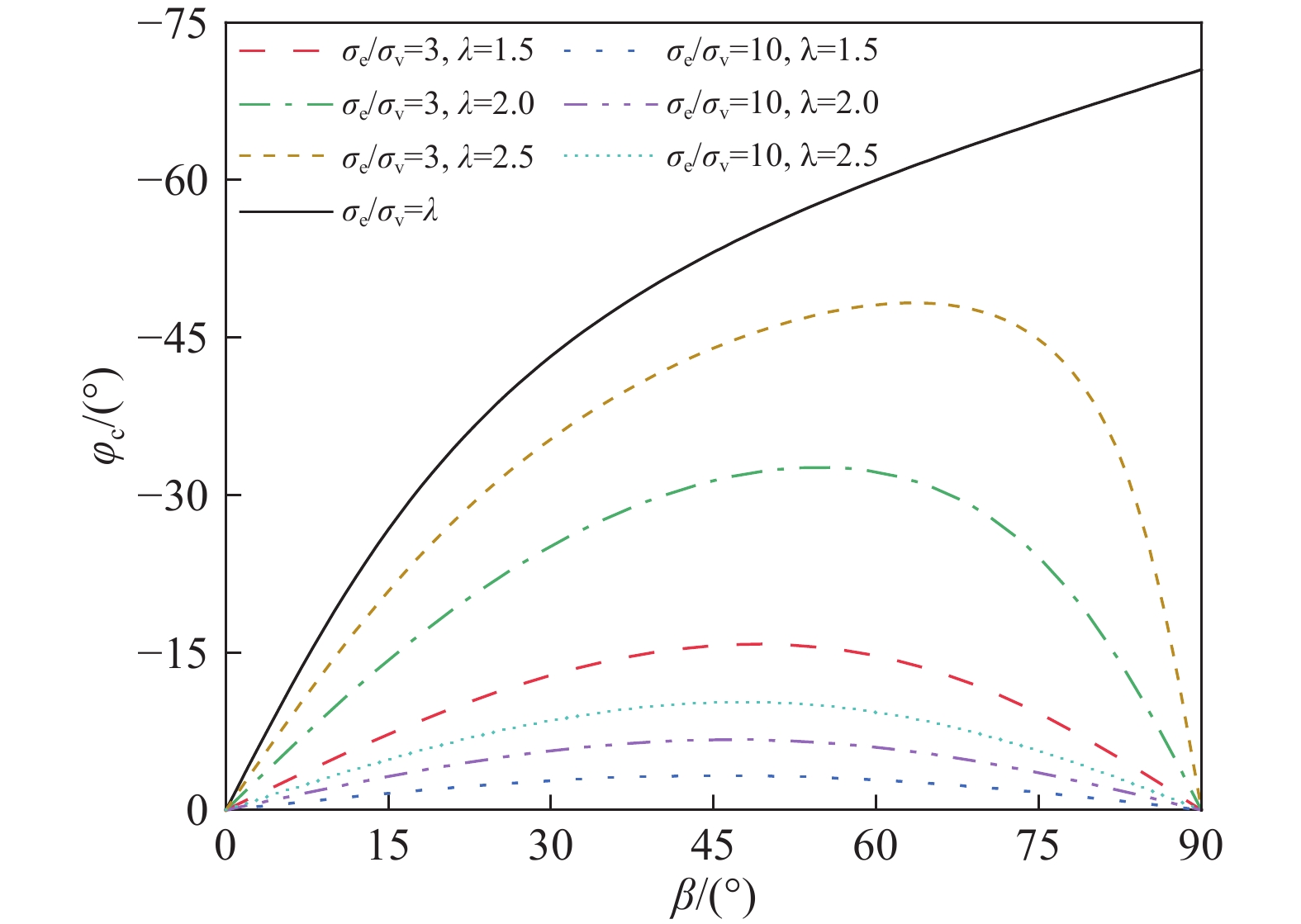

$$\begin{split} \left[ {{{{\sigma _{\rm{e}}}} \mathord{\left/ {\vphantom {{{\sigma _{\rm{e}}}} {{\sigma _{\rm{v}}}}}} \right. } {{\sigma _{\rm{v}}}}}{{ - }}\left( {{\text{co}}{{\text{s}}^2}\beta + \lambda {\text{si}}{{\text{n}}^2}\beta } \right)} \right]{\text{sin}}{\varphi _{\text{c}}} +\\ \left( {\lambda - 1} \right){\text{sin}}\beta {\text{cos}}\beta \left( {3{\text{cos}}{\varphi _{\text{c}}}{{ - }}1} \right){\text{ = }}0 \end{split}$$ (8) 由式(8)可知,当λ=1时,φc=0°,即裂隙扩展方向不受地应力作用影响;当λ≠1时,经计算可绘制不同地应力作用下裂隙方向角β与裂隙扩展方向角φc的关系,如图5所示。

当裂隙方向角β与远场地应力作用方向一致,即β为0°或90°时,φc=0°,表明煤体在起裂过程中不会发生偏转;在爆破初期σe/σv较大,裂隙扩展方向在爆破作用下沿原有爆生裂隙方向扩展;随着爆破能量衰减,σe/σv减小至10,此时裂隙扩展方向角φc随裂隙方向角β的增大呈先增大后减小的趋势,且对应同样的裂隙方向角β,裂隙扩展方向角φc随侧压系数λ的增大而增大;当σe/σv减小至3时,地应力对裂隙扩展方向的控制逐渐占据主导,随侧压系数λ的增大,裂隙扩展方向角φc变化越大。

同时,式(5)是确定裂隙偏转角的必要条件,裂隙只有在环向拉应力达到临界值时才会进一步扩展。根据爆炸载荷作用特点,σe/σv在短时间内会急剧减小,当σe/σv逐渐趋近于λ时,裂隙尖端应力强度因子很难达到断裂强度,当β趋近于90°时,由于水平应力相对较大,裂隙将转变为静态纯剪条件下的断裂形态。

1.4 聚能爆破煤体动态卸载效应分析

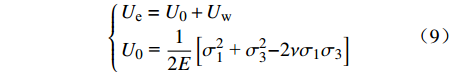

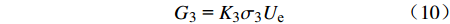

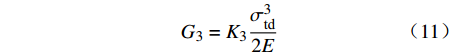

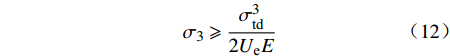

在爆破过程中,煤体受地应力、聚能爆破的耦合作用,前者由外向内挤压钻孔,后者由内向外冲击钻孔,因此在爆破正压作用阶段,地应力对爆破致裂有较大的阻碍作用。另一方面,地应力作用使钻孔围岩内积聚了弹性应变能,而爆破卸载使围岩发生“回弹”,即围岩在爆破正压作用后会在短时间内卸压,当爆炸载荷小于地应力时,钻孔围岩内的弹性应变能将开始沿爆炸空腔自由面释放形成卸载波,为进一步生成裂隙创造有利条件。煤体中积聚的可释放弹性应变能Ue为:

$$ \left\{ \begin{gathered} {U_{\text{e}}} = {U_0} + {U_{\rm{w}}} \\ {U_0}{\text{ = }}\dfrac{1}{{2E}}\left[ {\sigma _1^2{\text{ + }}\sigma _3^2{{ - }}2\nu {\sigma _1}{\sigma _3}} \right] \\ \end{gathered} \right. $$ (9) 其中:U0和Uw分别为地应力作用及爆破作用产生的弹性应变能;E为煤体的弹性模量;ν为泊松比。

基于能量耗散与释放原理的岩石破坏准则[26],在动态卸载过程中煤体破坏的能量释放率G3满足:

$$ {G_3}{\text{ = }}{K_3}{\sigma _3}{U_{\text{e}}} $$ (10) 其中,K3为材料常数。

当煤体的最小主应力σ3达到动态抗拉强度σtd时发生破坏,此时煤体的能量释放率为:

$$ {G_3} = {K_3}\dfrac{{\sigma _{{\text{td}}}^3}}{{2E}} $$ (11) 将式(11)代入式(10)可得到动态卸载时的破坏条件为:

$$ {\sigma _3} \geqslant \dfrac{{\sigma _{{\text{td}}}^3}}{{2{U_{\text{e}}}E}} $$ (12) 由式(12)可知,煤体破坏临界压力与可释放弹性应变能成反比,这表明煤体中可释放弹性应变能越大,煤体在动态卸载过程中更易破坏。而根据弹性应变能来源可知,地应力和爆破作用均会增加钻孔围岩中的可释放应变能,当爆破参数不变时,随着地应力增大,钻孔围岩中将积聚更多的弹性应变能。但随着地应力进一步增大,钻孔围岩在爆破前会发生形变破坏,导致爆炸能量在钻孔围岩破坏区发生较多损耗,围岩弹性应变能更多来自地应力作用。

2. 聚能爆破煤体致裂数值分析

2.1 模型的建立

为进一步探讨地应力对聚能爆破煤体致裂的作用,基于ANSYS/LS-DYNA建立数值计算模型,如图6所示。

模型尺寸为600 cm×600 cm×0.1 cm,且模型关于xoz、yoz平面对称,为提高计算效率,仅对模型右上部分进行求解。模型计算部分前后施加z方向约束,模型左侧及下侧施加对称约束,模型的上侧及右侧添加无反射边界条件,同时对模型上侧及右侧分别施加均布载荷σv、σh。在爆破数值模拟时需要先对煤体部分进行隐式分析,得到地应力作用下煤体的形变特征,在此基础上再进行显式动力分析,以实现动静耦合的作用过程[27-28]。炸药的爆轰压力用JWL状态方程[29]表示:

$$ \mathop P\nolimits_{\text{e}} = A(1 - \dfrac{\omega }{{\mathop \gamma \nolimits_1 \;V}})\mathop {\text{e}}\nolimits^{ - {\gamma _1}V} + B(1 - \dfrac{\omega }{{\mathop \gamma \nolimits_2 \;V}})\mathop {\text{e}}\nolimits^{ - {\gamma _2}V} + \dfrac{{\omega \mathop E\nolimits_0 }}{V} $$ (13) 其中:Pe为爆轰波压力,GPa;V为相对体积,m3;E0为炸药初始内能,GPa;A、B、γ1、γ2、ω均为与炸药材料相关的参数。试验采用煤矿许用三级乳化炸药,其相关参数分别为:密度1140 kg·m−3,爆速3200 m·s−1,A=246.1 GPa,B=10.26 GPa,γ1=7.177,γ2=2.401,ω=0.069,E0=4.19 GPa。煤体基础力学参数来自工程现场取样实测,煤体本构关系用HJC模型进行描述,通过添加关键字MAT_ADD_EROSION实现煤体的破坏失效。

2.2 不同地应力条件下的煤体裂隙发育特征

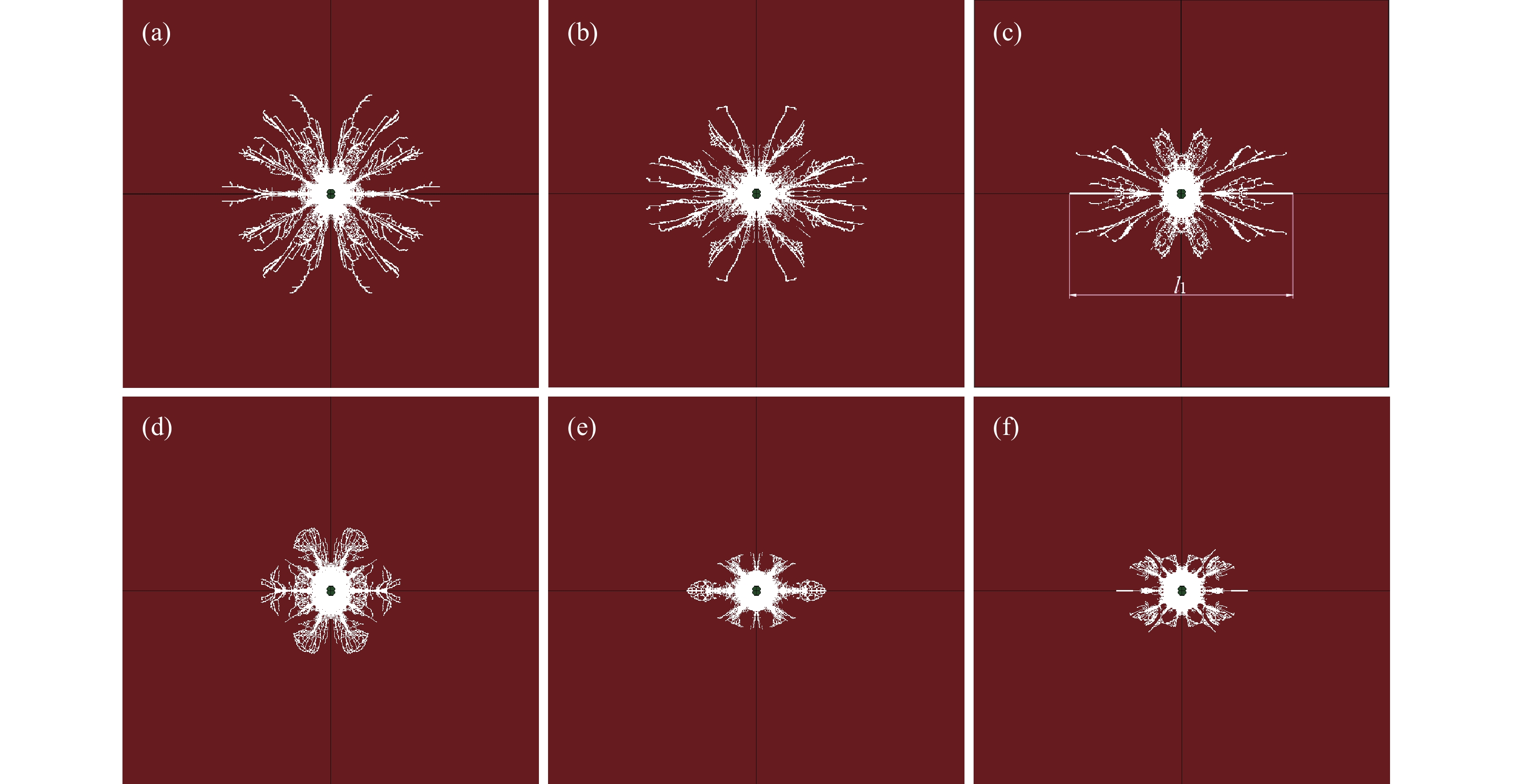

为探讨不同地应力条件下的煤体裂隙发育特征,结合试验区地应力分布情况,将远场压力σv设置为10 MPa、20 MPa,侧压系数λ分别设置为1、1.5、2,选取起爆后相同时刻(t=1000 μs)的爆生裂隙发育情况进行对比分析,如图7所示。

![]() 图 7 煤体爆生裂隙发育特征. (a) σv=10 MPa, λ=1; (b) σv=10 MPa, λ=1.5; (c) σv=10 MPa, λ=2;(d) σv=20 MPa,λ=1; (e) σv=20 MPa, λ=1.5; (f) σv=20 MPa, λ=2Figure 7. Development characteristics of coal cracks formed by blasting: (a) σv = 10 MPa, λ = 1; (b) σv = 10 MPa, λ = 1.5; (c) σv = 10 MPa, λ = 2; (d) σv=20 MPa, λ = 1; (e) σv = 20 MPa, λ = 1.5; (f) σv = 20 MPa, λ = 2

图 7 煤体爆生裂隙发育特征. (a) σv=10 MPa, λ=1; (b) σv=10 MPa, λ=1.5; (c) σv=10 MPa, λ=2;(d) σv=20 MPa,λ=1; (e) σv=20 MPa, λ=1.5; (f) σv=20 MPa, λ=2Figure 7. Development characteristics of coal cracks formed by blasting: (a) σv = 10 MPa, λ = 1; (b) σv = 10 MPa, λ = 1.5; (c) σv = 10 MPa, λ = 2; (d) σv=20 MPa, λ = 1; (e) σv = 20 MPa, λ = 1.5; (f) σv = 20 MPa, λ = 2当σv=10 MPa,λ=1时,煤体受聚能爆破作用在水平方向形成了较长的爆生主裂隙(图7(a))。当λ>1时,随着侧压系数增大,爆生裂隙在水平方向裂隙范围基本一致,而在竖直方向上裂隙扩展长度明显减小,分析认为在水平方向地应力增大的影响下,径向裂隙扩展受到了较大的阻碍作用,在竖直方向上尤为明显,同时可以看到在裂隙扩展后期,径向裂隙开始沿远场最大主应力方向偏转(图7(b)、(c))。

当σv=20 MPa,λ=1时,对比图7(a)、(d)可知,地应力的增大抑制了煤体径向张拉破坏,使径向裂隙扩展范围减小。煤体在爆破作用后,积聚在煤体中的弹性势能迅速释放,由此形成了环向裂隙(图7(d))。随着侧压系数增大,爆生裂隙在竖直方向的裂隙扩展范围明显减小(图7(e)、(f))。根据对比可知,聚能爆破裂隙在水平方向及竖直方向的扩展范围分别由地应力σv、σh控制,两者范围的比值由侧压系数λ决定。

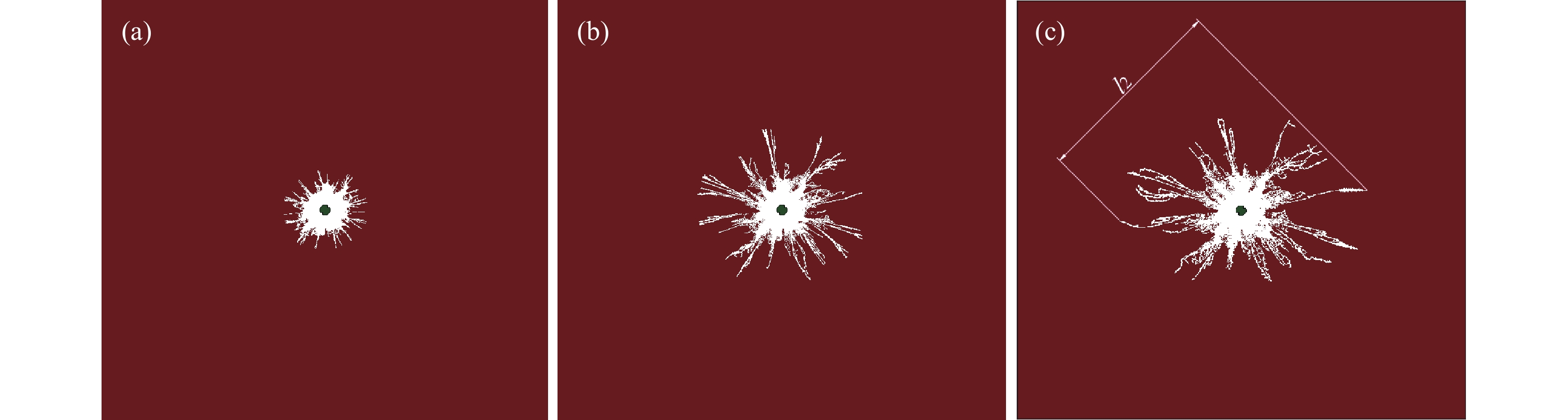

根据前述分析,地应力与聚能效应均对爆破裂隙扩展方向具有控制作用,为进一步明确地应力与爆炸应力场在裂隙扩展不同阶段的作用特征,需探讨聚能方向与最大主应力方向不一致的情况。将本文数值计算模型中的聚能药包绕z轴逆时针旋转45°,远场压力σv、σh分别设置为10 MPa、20 MPa,在其他条件不变的情况下得到煤体裂隙发育过程,如图8所示。

在聚能爆破作用初期,聚能流侵彻煤体在聚能方向上形成侵彻槽(图8(a))。随着裂隙进一步扩展,爆破作用逐渐减弱,地应力作用逐渐显现:在最小主应力方向上煤体受到的切向约束力较大,因此更难形成径向拉伸裂隙,制约了该方向上的裂隙扩展范围(图8(b));在非主应力方向,裂隙受剪切应力作用在扩展过程中逐渐向最大主应力方向偏转;在最大主应力方向上煤体所受切向约束力较小,进而形成了较大范围裂隙(图8(c))。

同时,采用Photoshop软件对图7(c)与8(c)中致裂区域,即图中白色区域进行周长统计后发现,在地应力条件相同的情况下,图7(c)中白色像周长比图8(c)多24.42%,而对比两者在聚能方向上的裂隙扩展范围,l1比l2大23.1%,表明聚能方向与最大主应力方向的夹角会对爆破致裂效果产生影响,地应力对聚能爆破裂隙扩展范围起到控制作用。从裂隙扩展方向来看,聚能爆破作用在裂隙形成初期占据主导,钻孔周围煤体在聚能流作用下形成定向裂隙。当爆破作用迅速衰减,地应力对裂隙扩展的影响逐渐增大,控制了爆生裂隙后期的发育形态。对于煤层增透而言,保持药包聚能方向与最大主应力方向一致有利于扩大裂隙表面积,对煤层瓦斯解吸具有积极意义。

2.3 聚能爆破煤体单元应力分析

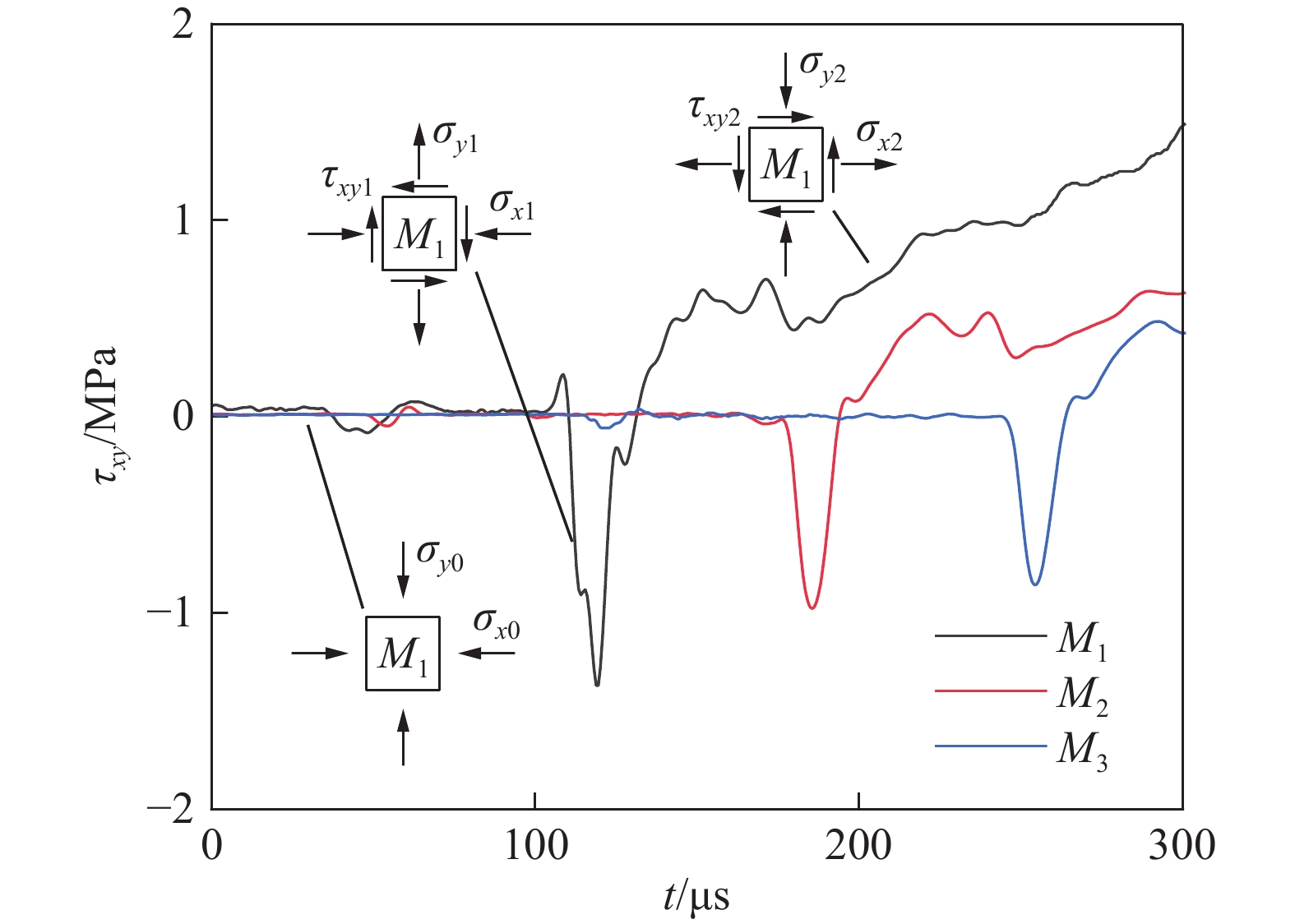

为进一步探讨地应力作用下聚能爆破裂隙偏转及弹性应变能释放的规律,通过煤体单元的受力情况进行研究。根据前述分析可知,当裂隙与最大主应力方向夹角β为0°或90°时,煤体在起裂过程中不会发生偏转,因此需要探讨β∈(0°,90°)的情况。以σv=10 MPa, λ=1.5条件为例,在模型第一象限的角平分上距离爆破孔中心20、30、40 cm选取M1、M2、M3共3个测点绘制剪切应力τxy的时程曲线,如图9所示。

其中,σxi、σyi、τxyi(i=0,1,2)分别表示测点单元M1在3个不同阶段所受沿x、y轴方向的正应力以及剪应力。当爆炸应力波未到达测点时,测点单元只受地应力作用,因此剪切应力τxy为0。当爆炸应力波经过测点时,可以看到3个测点依次到达波谷。根据剪应力符号可以判断此时测点单元的主应力方向绕逆时针旋转,但由于地应力的存在,使最大主应力方向无法完全转向45°角方向,随着爆炸应力波的进一步衰减,煤体单元的最大主应力方向逐渐趋于水平,这也是导致爆生裂隙并未沿应力波传播方向形成而是朝最大主应力方向偏转的原因。当爆炸应力波经过后,在地应力的作用下测点单元所受剪切应力与之前相反,这也使测点单元的主应力方向有朝顺时针方向旋转的趋势,即在爆破压缩作用过后,测点单元在地应力作用下逐渐恢复原有的主应力方向,但由于储存在单元内部弹性应变能的释放,导致测点单元的最大主应力方向再次发生改变,这也为形成环向裂隙创造了有利条件。

3. 深孔聚能爆破现场试验

3.1 试验工作面瓦斯地质条件

为研究地应力对深孔聚能爆破煤层致裂增透的作用,分别在平煤股份十矿己15-24100工作面、己15-33200工作面以及十二矿己15-33060工作面进行试验。试验工作面埋深分别为800~874 m、1022~1092.5 m、895~991 m,煤层平均倾角分别为13°、9°、12°,煤层平均厚度分别为2.1、2.4、3.3 m,煤层结构均比较稳定,节理裂隙较为发育,煤的坚固性系数在0.2~0.6之间,煤的破坏类型主要为Ⅱ、Ⅲ,煤层瓦斯压力最大值分别为2.95、2.5、1.8 MPa,瓦斯含量最大值分别为20.04、10.48、17.45 m³·t−1,均为突出煤层。

3.2 试验区地应力情况

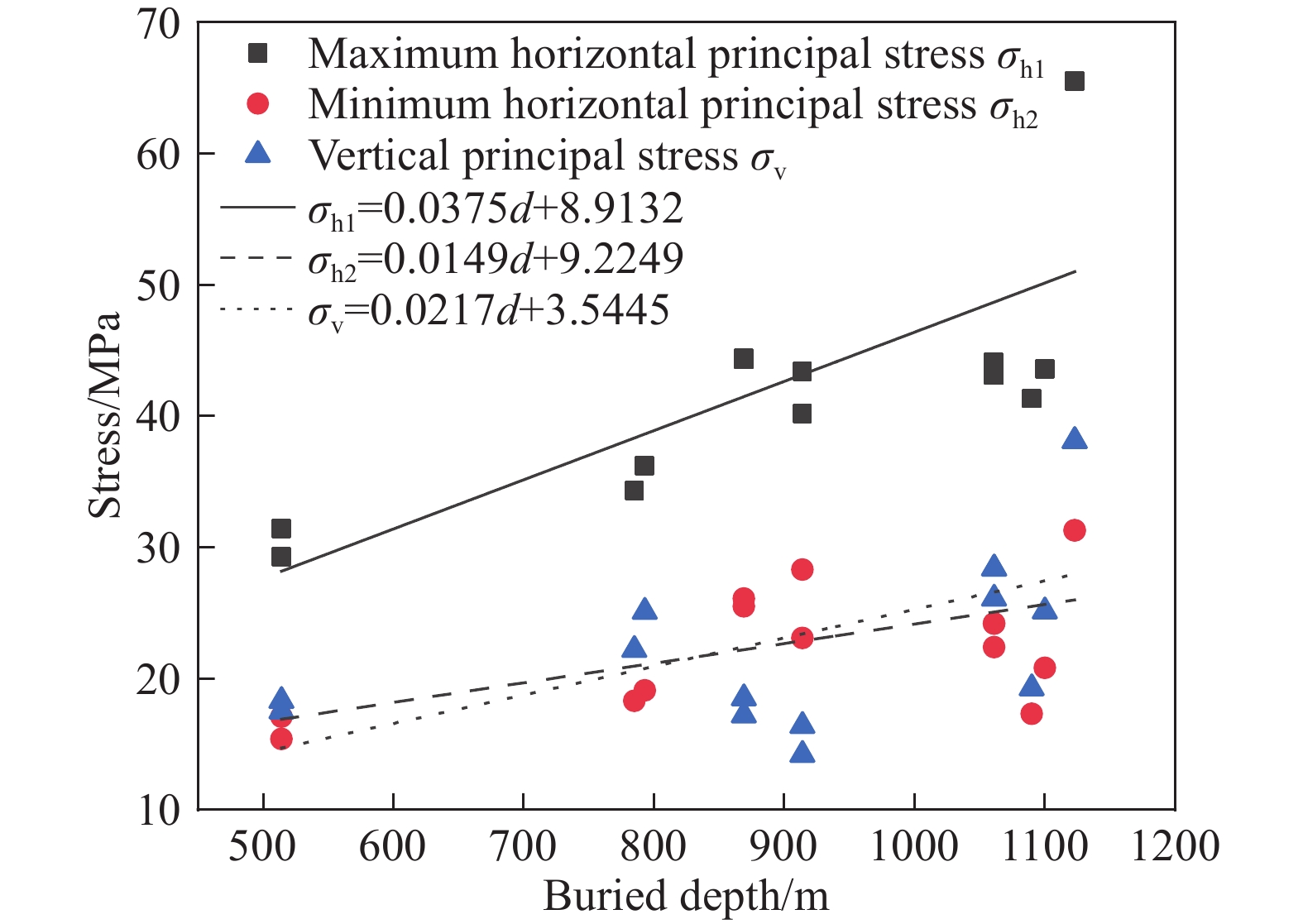

根据平煤股份十矿及十二矿地应力信息[30-32],试验区地应力总体随埋深d增加而增大,最大主应力倾角趋近于水平,方位角平均值为54.2°,大小约为最小主应力的2倍。如图10所示。

结合试验工作面埋深、钻孔方位角以及试验区地应力信息,得到钻孔远场应力如表1所示。

表 1 试验区钻孔远场围岩应力状态Table 1. Stress state of the surrounding rock of the borehole in the test areaExperimental

locationBuried

depth/mAzimuth/

(°)Dip angle/

(°)σh/MPa σv/MPa λ 24100

Working face≈ 837 22.2 13 26.9 21.7 1.24 31060

Working face≈ 943 34.5 35.5 32.3 23.4 1.38 33200

Working face≈ 1057 24.0 12 30.9 26.4 1.17 3.3 试验钻孔设计

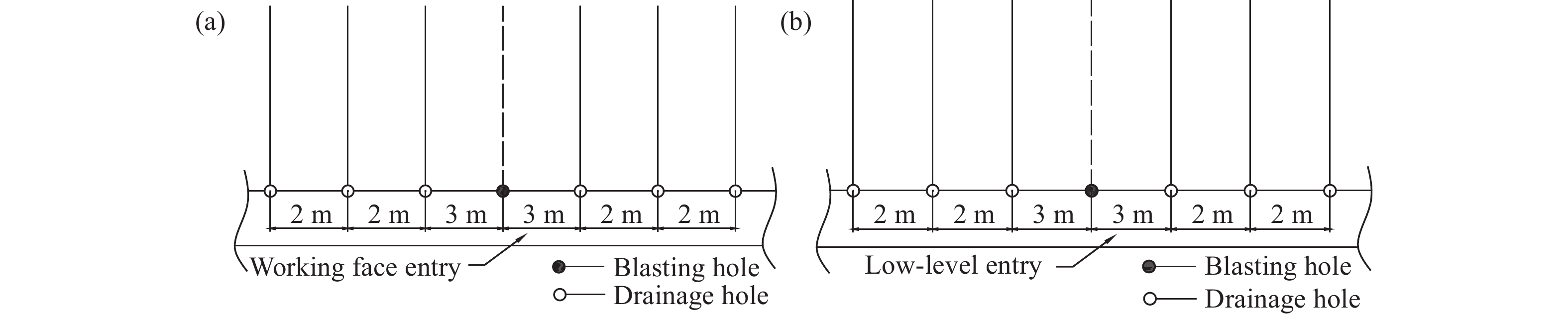

根据试验区瓦斯地质条件及现场工程条件,在平煤股份十矿己15-24100工作面和己15-33200工作面的试验钻孔布置如图11(a)所示,在平煤股份十二矿己15-31060工作面的试验钻孔布置如图11(b)所示。参考现场抽采孔的布置间距(2 m),并考虑到抽采钻孔间距不宜离爆破孔过近而影响抽采孔的封孔效果,同时抽采孔间距也不应过近使抽采孔相互之间产生较大影响,因此将爆破孔与抽采孔的间距定为3 m而抽采孔间距设置为2 m。为避免现场其他因素对试验结果来带的干扰,在每组试验地点均至少进行10次爆破试验,通过与爆破孔平行布置的抽采孔瓦斯抽采数据考察煤层致裂效果,进而探讨地应力对煤层致裂增透效果的影响。

3.4 试验结果分析

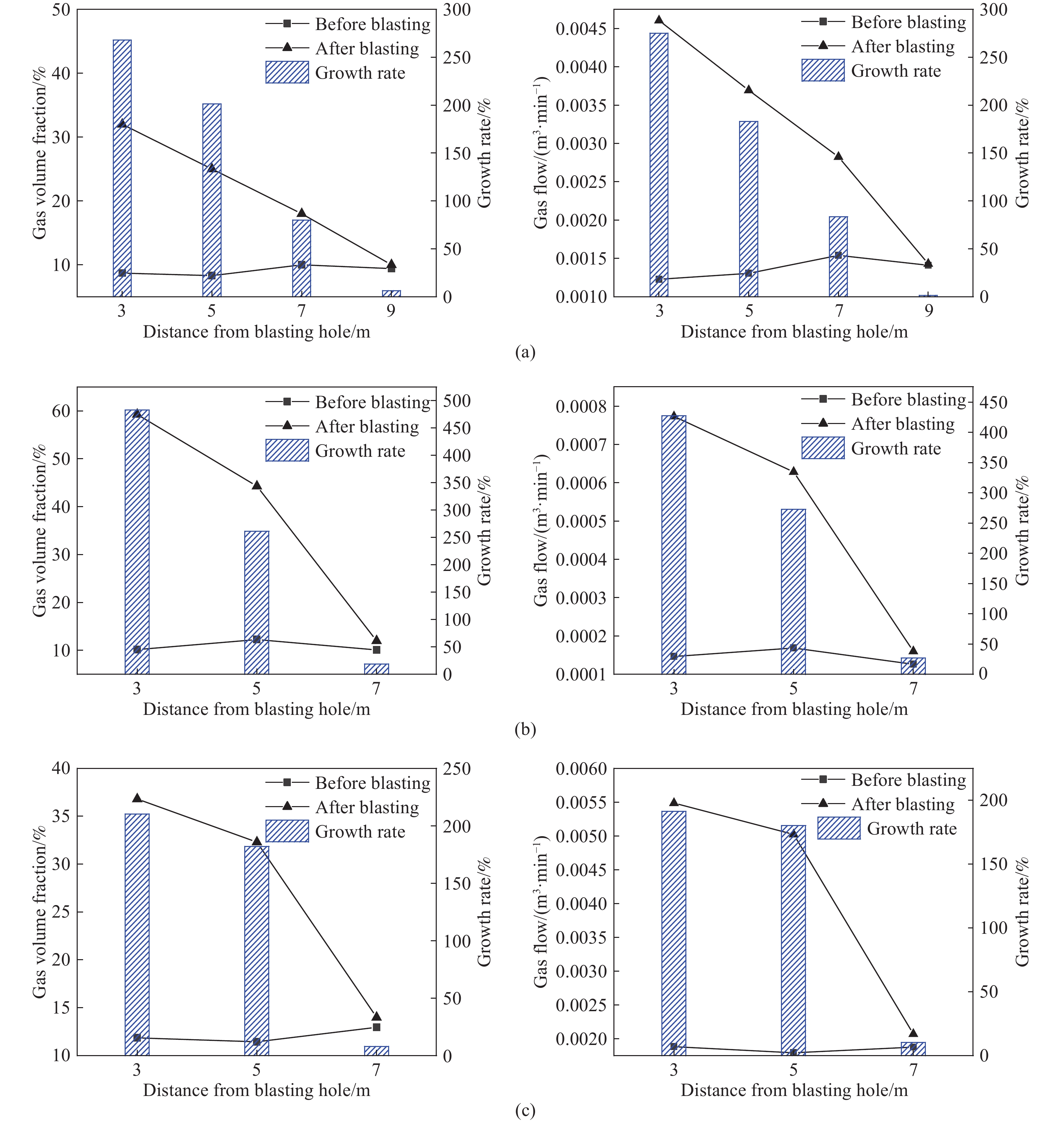

根据试验期间各抽采孔内瓦斯抽采数据,得到了聚能爆破前后抽采孔内瓦斯体积分数及纯流量变化(图12)。

试验后煤层瓦斯抽采效果在爆破孔附近5 m范围内均得到明显提升,距离爆破孔3 m处的抽采孔瓦斯体积分数增长率分别为267.8%、482.8%、210.3%,瓦斯纯流量增长率分别为275.1%、427.5%、191.3%,可以看出瓦斯体积分数与瓦斯纯流量的变化趋势较为接近;距离爆破孔5 m处的抽采孔瓦斯体积分数及纯流量增长率也存在相同的趋势,相比之下距离爆破孔越近增幅越大。随着抽采孔远离爆破孔,煤体受爆破作用逐渐减弱,爆生裂隙发育程度逐渐降低,使爆破增透效果出现一定下降。对比距离爆破孔7 m处的3组抽采孔瓦斯数据,抽采孔瓦斯体积分数增长率分别为80.0%、18.8%、8.1%,瓦斯纯流量增长率分别为83.4%、26.9%、10.3%,可以看出己15-24100工作面抽采孔爆破后瓦斯体积分数及纯流量增幅较为明显,而己15-31060工作面和己15-33200工作面的瓦斯抽采效果更为接近。对比图12(a)、图12(b)和图12(c),考虑到两抽采孔的影响范围有一定重叠,因此可以判断在己15-24100工作面的聚能爆破影响范围在7~8 m,而在己15-33060工作面及己15-33200工作面的聚能爆破影响范围在5~6 m之间。

对比3个试验区的钻孔地应力数据,三者在垂直应力大小方面呈线性递增的趋势,但却出现后两者聚能爆破影响范围较为接近的情况。分析认为,由于己15-31060工作面采用穿层钻孔,导致当药包聚能方向沿巷道走向布置时,钻孔围岩所受垂直及水平主应力与聚能药包存在一定夹角。根据前述模拟结果可知,当聚能方向与水平主应力方向不一致时,在聚能方向上的裂隙扩展范围会有所减小。这也造成了在己15-31060工作面距爆破孔7 m处的抽采孔瓦斯体积分数及纯流量增长率较低的情况,导致己15-33060工作面的聚能爆破影响范围与己15-33200工作面的聚能爆破影响范围更接近。

对试验结果分析可知,地应力在煤层深孔聚能爆破致裂增透中发挥重要作用,随着地应力升高,径向爆生裂隙的扩展受到影响较大,尤其在最小主应力方向上的裂隙会受到较强的切向应力,阻碍了裂隙的起裂及扩展过程,导致裂隙扩展范围变小。因此,为降低地应力对爆破致裂增透的作用,爆破孔轴线方向应尽量与最大主应力方向保持一致。而将爆破孔与抽采孔连线设置在最大主应力方向上将使爆生裂隙更容易与抽采孔贯通,从而达到更好的瓦斯抽采效果。

4. 地应力在聚能爆破煤层致裂不同阶段的作用探讨

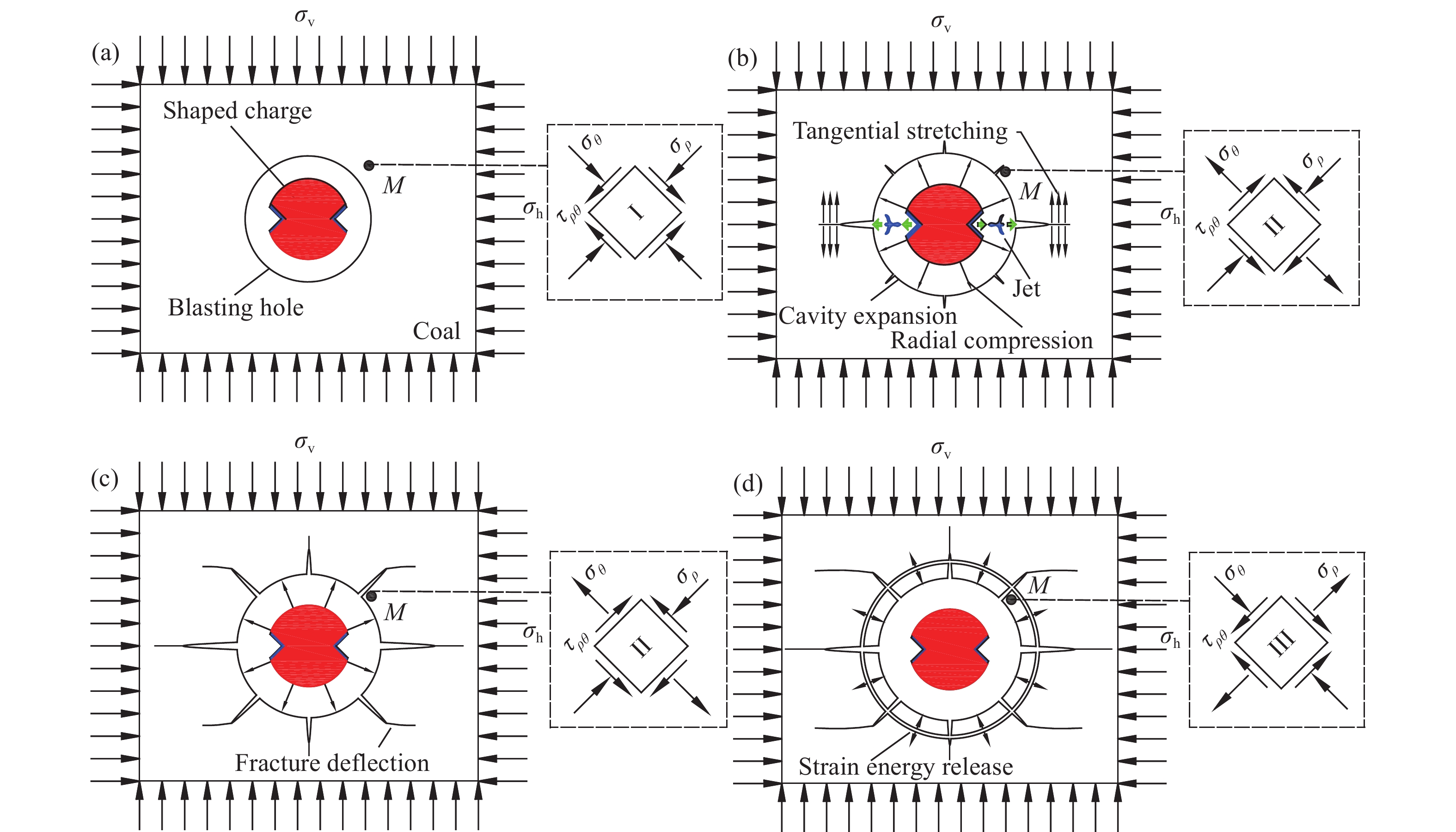

综合理论分析、数值模拟及现场试验结果,对地应力作用下的聚能爆破致裂过程进行探讨(以λ>1为例),并对聚能爆破孔外一点M的应力状态进行分析。

在进行聚能爆破前,爆破孔只受地应力作用(图13(a)),此时M点处于I型应力状态,若侧压系数为1,则剪应力τρθ为0;当聚能药包起爆,聚能流及爆轰产物作用于爆破孔,孔壁煤体被剧烈压缩形成爆破空腔并产生爆破粉碎区,随着爆炸冲击作用衰减,煤体无法发生压缩破坏,煤体单元转变为II型应力状态,在切向拉伸应力作用下产生径向裂隙(图13(b));当地应力主应力方向与径向应力方向不同时,随着聚能爆破作用的进一步减弱,处于II型应力状态的煤体单元将受到更强的剪应力作用导致煤体单元主应力方向朝地应力最大主应力方向偏转,从而导致裂隙扩展方向发生改变(图13(c));当爆破作用进一步减弱,煤体单元中储存的弹性应变能逐渐增大,当爆破产生的等效动态应力无法继续压缩钻孔围岩煤体时,煤体内的弹性应变能开始释放,形成拉伸应力,此时的煤体单元处于III型应力状态,使煤体沿爆破空腔方向产生环向裂隙(图13(d))。

![]() 图 13 地应力作用下的聚能爆破煤体致裂过程. (a) 钻孔初始受力阶段; (b) 聚能爆破作用主控阶段; (c) 地应力作用主控阶段; (d) 围岩动态卸载效应主控阶段Figure 13. Coal cracking process of cumulative blasting under in-situ stress: (a) initial stress stage of borehole; (b) main control stage of cumulative blasting; (c) main control stage of in-situ stress; (d) main control stage of surrounding rock dynamic unloading effect

图 13 地应力作用下的聚能爆破煤体致裂过程. (a) 钻孔初始受力阶段; (b) 聚能爆破作用主控阶段; (c) 地应力作用主控阶段; (d) 围岩动态卸载效应主控阶段Figure 13. Coal cracking process of cumulative blasting under in-situ stress: (a) initial stress stage of borehole; (b) main control stage of cumulative blasting; (c) main control stage of in-situ stress; (d) main control stage of surrounding rock dynamic unloading effect根据地应力作用下的聚能爆破裂隙发育特征以及煤体单元应力状态变化情况,可将聚能爆破致裂过程分依次为4个阶段:①钻孔初始受力阶段;②聚能爆破作用主控阶段;③地应力作用主控阶段;④围岩动态卸载效应主控阶段。不同阶段的控制因素存在较大区别:在阶段①,钻孔围岩受力状态及形变特征完全由钻孔形态以及地应力控制;在阶段②,煤体单元主要受聚能爆破冲击以及地应力的耦合作用,且聚能爆破冲击作用更强,因此该阶段的裂隙扩展方向主要由聚能装药结构主导;在阶段③,随着爆破能量向四周扩散,聚能爆破对煤体冲击作用逐渐减弱,当爆破等效动态应力衰减至与围岩应力在同一数量级时,地应力作用逐渐占据主导,爆生径向裂隙逐渐沿最大主应力方向偏转;在阶段④,当爆破等效动态应力小于围岩应力时,储存在煤岩体内的弹性应变能开始释放,且煤体受到拉伸应力达到动态抗拉强度σtd时发生破坏。

5. 结论

(1)地应力是影响煤层深孔聚能爆破径向裂隙扩展的主要因素。钻孔在地应力作用下产生切向压应力,限制了爆破径向裂隙扩展,减小了爆破致裂增透范围,而不同方向裂隙扩展范围比受侧压系数控制。煤层深孔聚能爆破裂隙初始扩展方向由聚能装药结构决定,随着爆破作用逐渐减弱,地应力作用进一步凸显,使煤体主应力方向逐渐与地应力方向一致,导致爆生裂隙朝最大主应力方向偏转。

(2)地应力作用下的动态卸载效应对煤层深孔聚能爆破裂隙生成具有促进作用。煤体受地应力作用先积聚了一定的可释放弹性应变能,随后在爆破作用下弹性应变能升高,待爆炸载荷无法使煤体进一步压缩时,弹性应变能沿爆炸空腔自由面开始释放形成卸载波,促进裂隙进一步生成。

(3)地应力在聚能爆破煤体致裂各阶段的作用有区别。根据聚能爆破裂隙发育特征将致裂过程依次划分为4个阶段:①钻孔初始受力阶段;②聚能爆破作用主控阶段;③地应力作用主控阶段;④围岩动态卸载效应主控阶段。地应力在聚能爆破过程中控制了钻孔初始破坏形态、爆生裂隙后期扩展方向及发育范围、煤体动态卸载破坏程度,而装药结构是决定聚能爆破初始裂隙扩展方向的主要因素。

-

图 7 煤体爆生裂隙发育特征. (a) σv=10 MPa, λ=1; (b) σv=10 MPa, λ=1.5; (c) σv=10 MPa, λ=2;(d) σv=20 MPa,λ=1; (e) σv=20 MPa, λ=1.5; (f) σv=20 MPa, λ=2

Figure 7. Development characteristics of coal cracks formed by blasting: (a) σv = 10 MPa, λ = 1; (b) σv = 10 MPa, λ = 1.5; (c) σv = 10 MPa, λ = 2; (d) σv=20 MPa, λ = 1; (e) σv = 20 MPa, λ = 1.5; (f) σv = 20 MPa, λ = 2

图 13 地应力作用下的聚能爆破煤体致裂过程. (a) 钻孔初始受力阶段; (b) 聚能爆破作用主控阶段; (c) 地应力作用主控阶段; (d) 围岩动态卸载效应主控阶段

Figure 13. Coal cracking process of cumulative blasting under in-situ stress: (a) initial stress stage of borehole; (b) main control stage of cumulative blasting; (c) main control stage of in-situ stress; (d) main control stage of surrounding rock dynamic unloading effect

表 1 试验区钻孔远场围岩应力状态

Table 1 Stress state of the surrounding rock of the borehole in the test area

Experimental

locationBuried

depth/mAzimuth/

(°)Dip angle/

(°)σh/MPa σv/MPa λ 24100

Working face≈ 837 22.2 13 26.9 21.7 1.24 31060

Working face≈ 943 34.5 35.5 32.3 23.4 1.38 33200

Working face≈ 1057 24.0 12 30.9 26.4 1.17 -

[1] 袁亮. 松软低透煤层群瓦斯抽采理论与技术. 北京: 煤炭工业出版社, 2004 Yuan L. Theory and Technology of Gas Drainage and Capture in Soft Multiple Coal Seams of Low Permeability Coal. Beijing. China Coal Industry Publishing House, 2004

[2] 穆朝民, 王海露, 黄文尧, 等. 高瓦斯低透气性煤体定向聚能爆破增透机制. 岩土力学, 2013, 34(9):2496 Mu C M, Wang H L, Huang W Y, et al. Increasing permeability mechanism using directional cumulative blasting in coal seams with high concentration of gas and low permeability. Rock Soil Mech, 2013, 34(9): 2496

[3] 刘健, 刘泽功, 高魁, 等. 深孔定向聚能爆破增透机制模拟试验研究及现场应用. 岩石力学与工程学报, 2014, 33(12):2490 Liu J, Liu Z G, Gao K, et al. Experimental study and application of directional focused energy blasting in deep boreholes. Chin J Rock Mech Eng, 2014, 33(12): 2490

[4] 郭德勇, 赵杰超, 张超, 等. 煤层深孔聚能爆破控制孔作用机制研究. 岩石力学与工程学报, 2018, 37(4):919 Guo D Y, Zhao J C, Zhang C, et al. Mechanism of control hole on coal crack initiation and propagation under deep-hole cumulative blasting in coal seam. Chin J Rock Mech Eng, 2018, 37(4): 919

[5] Guo D Y, Lv P F, Zhao J C, et al. Research progress on permeability improvement mechanisms and technologies of coalbed deep-hole cumulative blasting. Int J Coal Sci Technol, 2020, 7(2): 329 doi: 10.1007/s40789-020-00320-5

[6] 何满潮, 谢和平, 彭苏萍, 等. 深部开采岩体力学研究. 岩石力学与工程学报, 2005, 24(16):2803 doi: 10.3321/j.issn:1000-6915.2005.16.001 He M C, Xie H P, Peng S P, et al. Study on rock mechanics in deep mining engineering. Chin J Rock Mech Eng, 2005, 24(16): 2803 doi: 10.3321/j.issn:1000-6915.2005.16.001

[7] 谢和平. 深部岩体力学与开采理论研究进展. 煤炭学报, 2019, 44(5):1283 Xie H P. Research review of the state key research development program of China: Deep rock mechanics and mining theory. J China Coal Soc, 2019, 44(5): 1283

[8] Fairhurst C. Some challenges of deep mining. Engineering, 2017, 3(4): 527 doi: 10.1016/J.ENG.2017.04.017

[9] 赵宝友, 王海东. 深孔爆破技术在高地应力低透气性高瓦斯煤层增透防突中的适用性. 爆炸与冲击, 2014, 34(2):145 doi: 10.11883/1001-1455(2014)02-0145-08 Zhao B Y, Wang H D. Feasibility of deep-hole blasting technology for outburst prevention and permeability enhancement in high-gas-content coal seams with low-permeability subjected to high geo-stresses. Explos Shock Waves, 2014, 34(2): 145 doi: 10.11883/1001-1455(2014)02-0145-08

[10] 肖思友, 姜元俊, 刘志祥, 等. 高地应力下硬岩爆破破岩特性及能量分布研究. 振动与冲击, 2018, 37(15):143 doi: 10.13465/j.cnki.jvs.2018.15.020 Xiao S Y, Jiang Y J, Liu Z X, et al. Hard rock blasting energy distribution and fragmentation characteristics under high earth stress. J Vib Shock, 2018, 37(15): 143 doi: 10.13465/j.cnki.jvs.2018.15.020

[11] Zhao J J, Zhang Y, Ranjith P G. Numerical modelling of blast-induced fractures in coal masses under high in situ stresses. Eng Fract Mech, 2020, 225: 106749 doi: 10.1016/j.engfracmech.2019.106749

[12] Kutter H K, Fairhurst C. On the fracture process in blasting. Int J Rock Mech Min Sci Geomech Abstr, 1971, 8(3): 181 doi: 10.1016/0148-9062(71)90018-0

[13] 穆朝民. 爆炸荷载和地应力耦合作用下煤体裂纹扩展的模型实验研究. 实验力学, 2012, 27(4):511 Mu C M. Model investigation on coal crack growth under coupling action of blasting loads and crustal stress. J Exp Mech, 2012, 27(4): 511

[14] 穆朝民, 潘飞. 煤体在爆炸荷载和地应力耦合作用下裂纹扩展的数值模拟. 高压物理学报, 2013, 27(3):403 doi: 10.11858/gywlxb.2013.03.014 Mu C M, Pan F. Numerical study on the damage of the coal under blasting loads coupled with geostatic stress. Chin J High Press Phys, 2013, 27(3): 403 doi: 10.11858/gywlxb.2013.03.014

[15] 陈明, 卢文波, 周创兵, 等. 初始地应力对隧洞开挖爆生裂隙区的影响研究. 岩土力学, 2009, 30(8):2254 doi: 10.3969/j.issn.1000-7598.2009.08.009 Chen M, Lu W B, Zhou C B, et al. Influence of initial in situ stress on blasting-induced cracking zone in tunnel excavation. Rock Soil Mech, 2009, 30(8): 2254 doi: 10.3969/j.issn.1000-7598.2009.08.009

[16] Tao J, Yang X G, Li H T, et al. Effects of in-situ stresses on dynamic rock responses under blast loading. Mech Mater, 2020, 145: 103374 doi: 10.1016/j.mechmat.2020.103374

[17] Yang L Y, Ding C X. Fracture mechanism due to blast-imposed loading under high static stress conditions. Int J Rock Mech Min Sci, 2018, 107: 150 doi: 10.1016/j.ijrmms.2018.04.039

[18] Yang R S, Ding C X, Li Y L, et al. Crack propagation behavior in slit charge blasting under high static stress conditions. Int J Rock Mech Min Sci, 2019, 119: 117 doi: 10.1016/j.ijrmms.2019.05.002

[19] Lu W B, Yang J H, Yan P, et al. Dynamic response of rock mass induced by the transient release of in situ stress. Int J Rock Mech Min Sci, 2012, 53: 129 doi: 10.1016/j.ijrmms.2012.05.001

[20] Zhang F P, Peng J Y, Qiu Z G, et al. Rock-like brittle material fragmentation under coupled static stress and spherical charge explosion. Eng Geol, 2017, 220: 266 doi: 10.1016/j.enggeo.2017.02.016

[21] Xiao S Y, Su L J, Jiang Y J, et al. Numerical analysis of hard rock blasting unloading effects in high in situ stress fields. Bull Eng Geol Environ, 2019, 78(2): 867 doi: 10.1007/s10064-017-1067-7

[22] 郭德勇, 赵杰超, 吕鹏飞, 等. 煤层深孔聚能爆破动力效应分析与应用. 工程科学学报, 2016, 38(12):1681 Guo D Y, Zhao J C, Lü P F, et al. Dynamic effects of deep-hole cumulative blasting in coal seam and its application. Chin J Eng, 2016, 38(12): 1681

[23] 吴顺川. 岩石力学. 北京: 高等教育出版社, 2021 Wu S C. Rock Mechanics. Beijing: Higher Education Press, 2021

[24] Sih G C, Paris P C, Erdogan F. Crack-tip, stress-intensity factors for plane extension and plate bending problems. J Appl Mech, 1962, 29(2): 306 doi: 10.1115/1.3640546

[25] Williams J G, Ewing P D. Fracture under complex stress—The angled crack problem. Int J Fract, 1972, 8(4): 441 doi: 10.1007/BF00191106

[26] 谢和平, 鞠杨, 黎立云. 基于能量耗散与释放原理的岩石强度与整体破坏准则. 岩石力学与工程学报, 2005, 24(17):3003 doi: 10.3321/j.issn:1000-6915.2005.17.001 Xie H P, Ju Y, Li L Y. Criteria for strength and structural failure of rocks based on energy dissipation and energy release principles. Chin J Rock Mech Eng, 2005, 24(17): 3003 doi: 10.3321/j.issn:1000-6915.2005.17.001

[27] Yang J H, Jiang Q H, Zhang Q B, et al. Dynamic stress adjustment and rock damage during blasting excavation in a deep-buried circular tunnel. Tunn Undergr Space Technol, 2018, 71: 591 doi: 10.1016/j.tust.2017.10.010

[28] Tao M, Li X B, Wu C Q. Characteristics of the unloading process of rocks under high initial stress. Comput Geotech, 2012, 45: 83 doi: 10.1016/j.compgeo.2012.05.002

[29] Livermore Software Technology Corporation. LS-DYNA keyword users manual: version 971 [Z/OL]. LSTC (2007-05)[2022-01-25].https://www.dynasupport.com/manuals/ls-dyna-manuals/ls-dyna-971/view

[30] 张建国. 平顶山矿区深井动力灾害灾变机理及防治关键技术研究[学位论文]. 徐州: 中国矿业大学, 2012 Zhang J G. Study on the Disaster Mechanism and Prevention Key Technologies of Deep Mine Dynamic Disasters in Pingdingshan Coal Mine [Dissertation]. Xuzhou: China University of Mining and Technology, 2012

[31] 蔡美峰, 郭奇峰, 李远, 等. 平煤十矿地应力测量及其应用. 北京科技大学学报, 2013, 35(11):1399 Cai M F, Guo Q F, Li Y, et al. In situ stress measurement and its application in the 10th Mine of Pingdingshan Coal Group. J Univ Sci Technol Beijing, 2013, 35(11): 1399

[32] 王迎超, 靖洪文, 陈坤福, 等. 平顶山矿区地应力分布规律与空间区划研究. 岩石力学与工程学报, 2014, 33(增刊1): 2620 Wang Y C, Jing H W, Chen K F, et al. Study of distribution regularities and regional division of in situ stresses for Pingdingshan mining area. Chin J Rock Mech Eng, 2014, 33(Suppl 1): 2620

-

期刊类型引用(13)

1. 张鑫,刘泽功,常帅,陈响升,薛勇林,朱家亮,宋鑫. 爆破荷载作用下煤岩本构模型参数特性研究. 振动与冲击. 2025(05): 263-277 .  百度学术

百度学术

2. 黄高翔,许国庆,姚强,杨旭,陈星艮,李洪涛. 小断面隧洞聚能水压光面爆破试验. 爆破. 2025(01): 89-96 .  百度学术

百度学术

3. 王永法. 防隔水煤柱切顶卸压定向爆破参数设计及工程应用. 煤炭工程. 2024(02): 1-9 .  百度学术

百度学术

4. 付建军,李忠,郝秀明. 定向深孔造穴煤层瓦斯抽采效果的影响因素研究. 煤. 2024(05): 82-86 .  百度学术

百度学术

5. 李萍丰,王秀龙,闫小兵,马正腾,彭建宇,张凤鹏. 柱状药包侧向爆破下抵抗线对岩石破碎特性的影响研究. 岩土力学. 2024(05): 1388-1396 .  百度学术

百度学术

6. 郭建,孙博闻,姚颖康,王海亮,缪玉松,张义平. 起爆方式对爆轰波传播特性的影响研究. 青岛理工大学学报. 2024(03): 35-42 .  百度学术

百度学术

7. 杨帅,刘泽功,常帅,张健玉,傅师贵,乔国栋,张鑫. 地应力作用下聚能爆破煤体损伤特征试验研究. 采矿与安全工程学报. 2024(05): 1078-1090 .  百度学术

百度学术

8. 杨帅,刘泽功,张健玉,傅师贵,乔国栋,张鑫,常帅. 爆炸荷载作用下深部煤体损伤特征试验研究. 振动与冲击. 2024(19): 276-286 .  百度学术

百度学术

9. 张健玉,刘泽功,傅师贵,乔国栋,张鑫,杨帅. 深部松软高瓦斯煤层底板岩层深孔聚能控制爆破增透研究. 采矿与安全工程学报. 2024(06): 1311-1322 .  百度学术

百度学术

10. 张琳,胡少斌,蔡余康,庞烁钢,颜正勇. 地应力对高温高压CO_2热冲击破岩的影响研究. 地下空间与工程学报. 2024(06): 1818-1829 .  百度学术

百度学术

11. 田宇,高魁,李亮,李梦娣. 爆破扰动不含断层煤岩及逆断层煤岩裂隙演化对比实验. 中国安全生产科学技术. 2023(05): 86-92 .  百度学术

百度学术

12. 宗琦,王富强,汪海波,吕闹,程兵,王梦想. 对称多向聚能装药爆破破岩效果数值模拟研究. 安徽理工大学学报(自然科学版). 2023(03): 67-72 .  百度学术

百度学术

13. 高志刚,冯友德,张博文,张晴,韩新磊,杨亮. 石墨尾矿制备爆破封孔材料试验研究. 现代矿业. 2023(07): 200-204 .  百度学术

百度学术

其他类型引用(9)

下载:

下载: